Process

We make oil the way it was made 100 and 200 years ago.

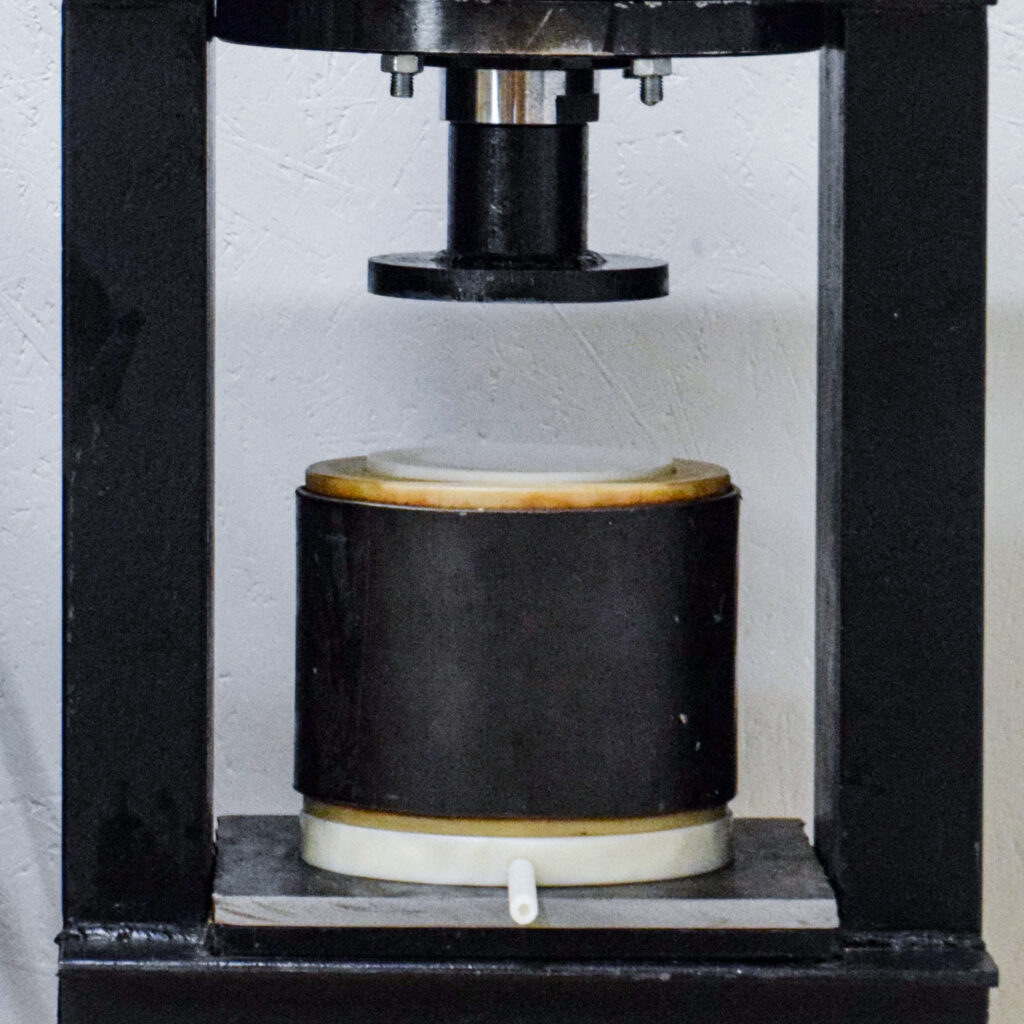

It is a simple mechanical pressing of seeds and nuts.

Of course, technology and materials have changed over time - they are now more modern and.

higher quality.

But the principle remains the same: to produce genuine, living oil that retains all the properties of the

natural properties.

The whole process looks like this:

In such a process:

Equipment and materials used:

- we do not heat seeds or nuts,

- we do not heat the oil,

- the oil does not heat up during the production process - it remains at room temperature.

Why is this important? Especially for linseed, heating causes

polyunsaturated fatty acids and certain vitamins, and the protein structure

alteration (denaturation).

In addition, our oil does not come into contact with metals at any stage of production. This prevents

oxidation, as metal is a catalyst in oxidation processes.

It is thanks to these simple but essential principles that our oil is alive. All

minerals, vitamins and useful nutrients that nature has put into seeds and oil are essential for our oil.

in seeds and nuts are preserved in our oil.

Equipment and materials used:

One drum can hold 2 kg of seeds or nuts and the oil pressing takes 4-24 hours.

As you can see, this work requires patience and time.

We will only start pressing the oil once we receive your order. Therefore, every

the customer always specially for him freshly pressed live oil.